Used Packaging Machinery

Nationwide Distributor of Used Packaging Machinery

Nationwide Distributor of Used Packaging Machinery

AmerEquip International, located in New York, offers some of the best quality used packaging machinery and equipment in the industry. While we are located in New York we can ship and service all of those in need across the country.

With our used packaging machines, control of the amount of a product in each box or container is strikingly more efficient. It is vital for medications in particular to have the correct dosage and quantity in each bottle or pouch. Keeping track of inventory is simple by making these separations. Without packaging machinery, the entire economy would be different. Different industries require different packaging. Some of the more popular types of packaging includes:

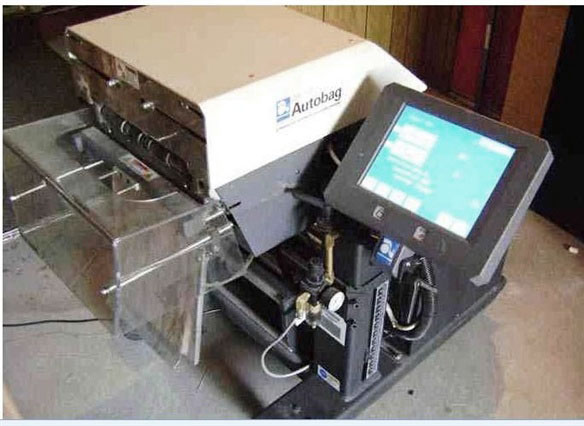

At AmerEquip, we pride ourselves on the great selection of used packaging machinery that is available at great, affordable rates. By understanding the differences with different types of machinery, you can better work your business or company. We also buy and sell case sealers that helps with many packaging applications. We stand behind all of the used equipment we sell 100%, as it has all been fully refurbished.

Materials for Packaging

Through trial and error over the centuries, several different materials are now ubiquitous in packaging which is assembled by a machine. Common materials are glass, plastic, cardboard, foam and aluminum. Foam is commonly used for fitting large heavy items (computers, flat screen TVs and air conditioners) as well as small fragile items such as porcelain figurines. Aluminum is found holding beverages and food in can form.

Glass may be a fragile material for most cases, especially depending on thickness, however it does not decay and is great for preserving food. This is unlike plastic, which breaks down slowly over time and needs to be recycled as it does not decompose.

Cardboard typically comes in box form and easily holds multiple cans or jars. One downside to cardboard is its inability to hold up well to water. Due to this, it can grow mildew, soften and break apart causing a mess and an inconvenience. But no matter the material, the aim for these machines is to safely transport goods.

Unique Used Packaging Machinery

Over the years, the marketing industry has found new innovative way to make packaging more appealing to consumers. While some products have maintained their design over the years, others have made adjustments to compete with other brands. Sometimes the packaging style is unique or smart, whether it is to get your attention or just makes more sense economically. Browse through our selection of great used packaging equipment.

We are constantly updating our inventory and getting new packaging equipment and machines. If you do not see what you are looking for on our used packaging equipment page, then be sure to check out what we have in new arrivals.

Packaging Machinery Types

As mentioned above, there are many forms of packaging throughout the industry. The various used packaging machinery can handle shrink wrapping, clamshells, void fill, stretch wrapping, sealed tray, fin seal, folding carton, and blister packs.

Blister Packaging

Although you may never hear the term blister packaging in public, it is actually a very common style of packaging for consumer goods. It usually consists of a thin plastic covering over the product, which is all affixed to a cardboard back. Typically, blister packing is used for pills, tablets and other pharmaceuticals. They are also found with action figures, hardware or anything else the manufacturer thinks is suitable for protection on the store shelves. Learn more about the uses of blister packaging.

Cottoners

Cottoners are also for pills, but instead of a plastic package, these machines continuously place cotton into bottles already filled with the medication. There are two styles of cottoners:

- Inline: This type features a conveyor system to package.

- Rotary: A rotary cottoner has a rotary disc with several inserting heads.

Each style of cottoner comes with specific requirements, so it depends on what sort of items you are packaging. While the bottles may be fine without cotton on the retail shelf, it's when they are transported that cotton needs to be in there to fill the void so the pills do not break.

Void Fill

Void fill is a filler material that companies use to close up the free space in a shipping box. By doing so, it locks products in place in the box. When items are limited from movement during shipping, then the likelihood of damage goes way down. Paper-based filler offers excellent physical properties by being able to absorb shocks and protect sensitive products. Paper-based filler is also more eco-friendly than its alternatives, but there are other materials you can use in order to create void fill for shipping purposes.

New York Packaging Machinery Supplier

AmerEquip is located in New York, but ships to businesses nationwide. We can supply all of your used packaging machinery needs and keep your products safe during transport. Feel free to contact us for further details on our wide range of used and new packaging equipment and machines.

The number to call is (845) 628 8824. We will gladly answer any questions or concerns you may have about our range of products, as well as provide you with a free quote on our used packaging machinery. We have years of experience as a trusted distributor and aim to supply you with whatever machinery or equipment you need for your needs.